Why Dry Your Printed Circuit Boards (PCBs)?

01.07.2014

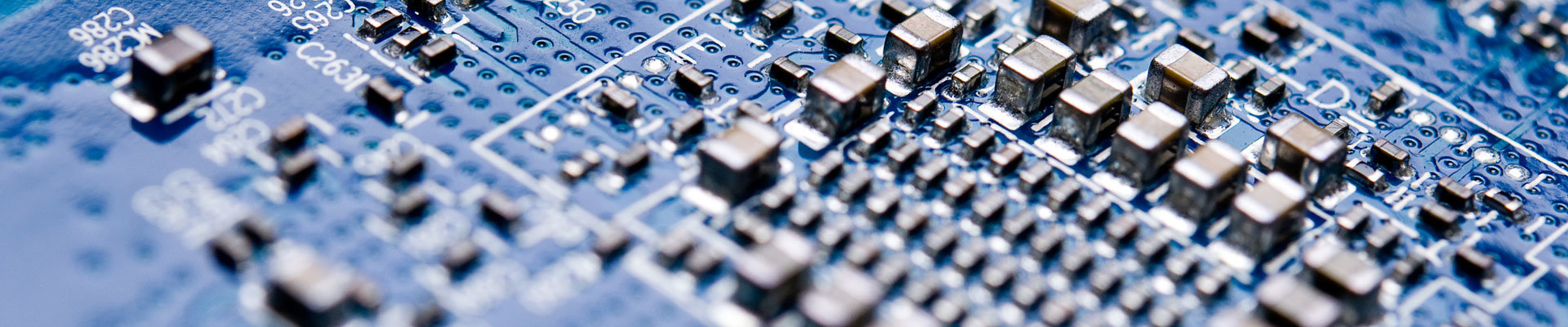

Delamination is a well-known problem in the production of printed circuit boards (PCBs). This occurs due to moisture contained within the PCB, which turns into vapor quickly during the heating process.

Delamination is a well-known problem in the production of printed circuit boards (PCBs). This occurs due to moisture contained within the PCB, which turns into vapor quickly during the heating process. Because this vapor has no way to evaporate off, it generates high pressure within the board, which can lead to the formation of blisters, faulty soldering joints, and barrel cracks. Such defects can contribute to circuit failures and the PCBs must be discarded.

In order to minimize this risk, we recommend that you let all of your single and double-sided PCBs be professionally dried. Drying is especially recommended for Flex, Star-Flex, and multilayer boards. If you source your PCBs in Asia, this issue is particularly important because these boards are often given a shorter period of time in which to dry – thus increasing the risk of defects.

At ESO, we dry PCBs in a convection drying oven at 120°C (248°F) for 2 hours. After drying, it is our policy that the boards will then be assembled in our factory within the next 24 hours. Should you have more specific instructions or requirements for drying and storing PCBs (e.g. for multilayer Starflex boards), please let us know and we will modify our production process to suit your needs.